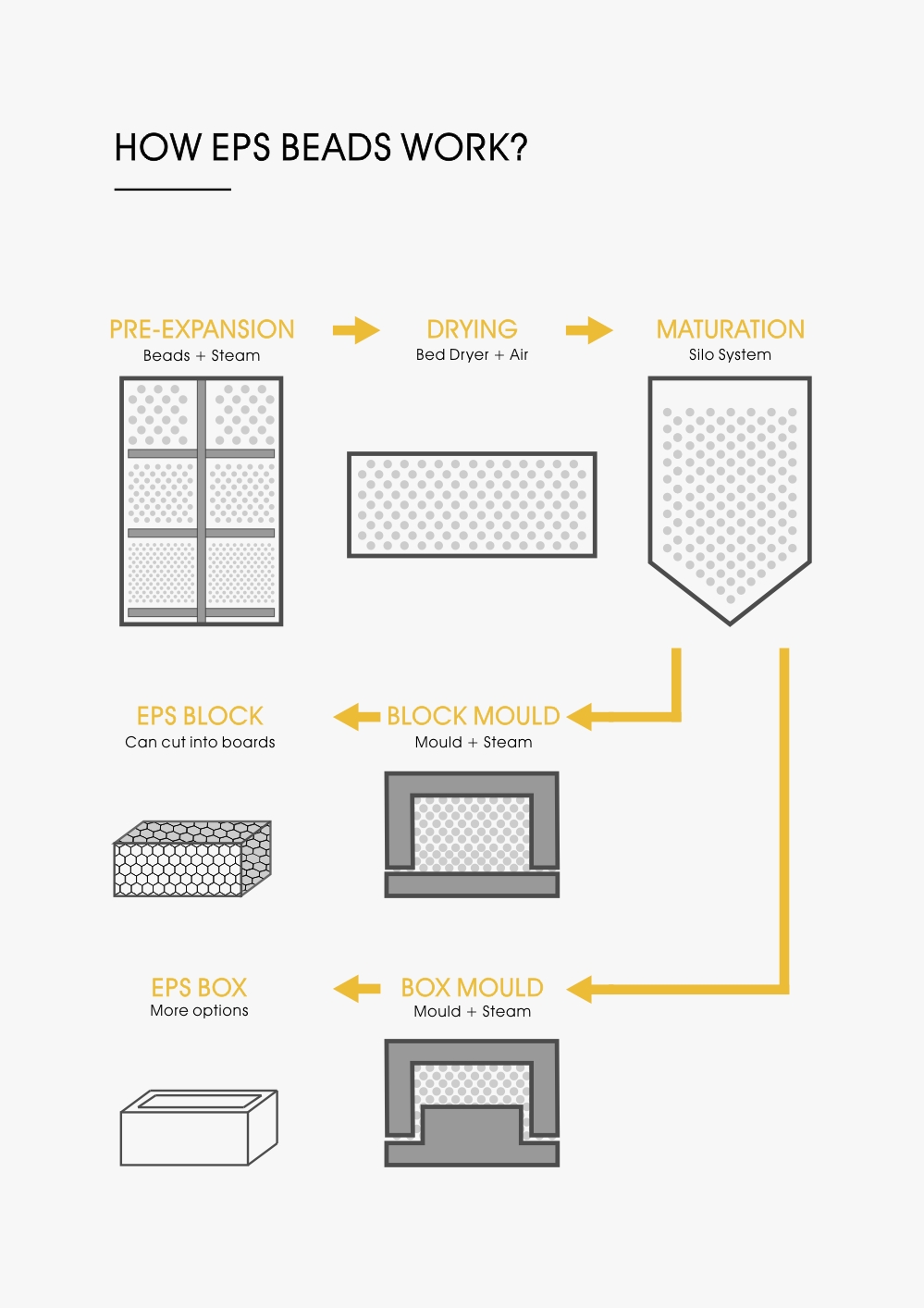

Composition and Manufacturing Process:

- Raw Material: EPS (Expanded Polystyrene) begins as polystyrene resin, a petroleum-based polymer, formed into small, dense beads containing a blowing agent, typically pentane.

- Heat Application:: When heated (via steam), the blowing agent (pentane) vaporizes, creating pressure within the beads.

- Expansion: The polystyrene softens above its glass transition temperature, allowing the gas to expand the beads up to 50 times their original size. This forms closed-cell foam structures filled with air and pentane.

- Stabilization: Expanded beads are cooled, stabilizing their structure and allowing air to replace some pentane.

Molding Process:

- Mold Loading: Pre-expanded beads are placed into a mold of the desired shape.

- Steam Fusion: Steam is reapplied, softening the beads' surfaces. Pressure fuses them together at contact points, forming a cohesive structure while retaining cellular integrity.

- Cooling and Demolding: The molded product cools, hardening into a rigid yet lightweight form.

Key Properties:

- Lightweight: Composed mostly of air (up to 98%), making EPS easy to handle.

- Thermal Insulation: Trapped air pockets reduce heat transfer, ideal for construction and packaging.

- Shock Absorption: Compressible cells absorb impact, protecting fragile items.

- Moisture Resistance: Closed-cell structure minimizes water absorption.

- Buoyancy: High buoyancy due to low density, used in flotation devices.

Applications:

- Packaging: Protects electronics, appliances, and fragile goods.

- Construction: Insulation boards for walls, roofs, and foundations.

- Food Industry: Disposable containers and cups.

- Specialized Uses: Geofoam for lightweight fill, craft materials, and life jackets.